Efficiency at every layer: smart crate solution for TOP Onions

At TOP Onions in ‘s-Gravenpolder, Zeeland, everything revolves around craftsmanship, quality and efficient work. The internationally active family business has been growing and processing onions of all shapes and sizes for more than 25 years. To further increase processing capacity and reduce repetitive work, TOP Onions chose a compact crate unfolding machine from Reintjes Systems in 2022.

Smart, fast and space-saving

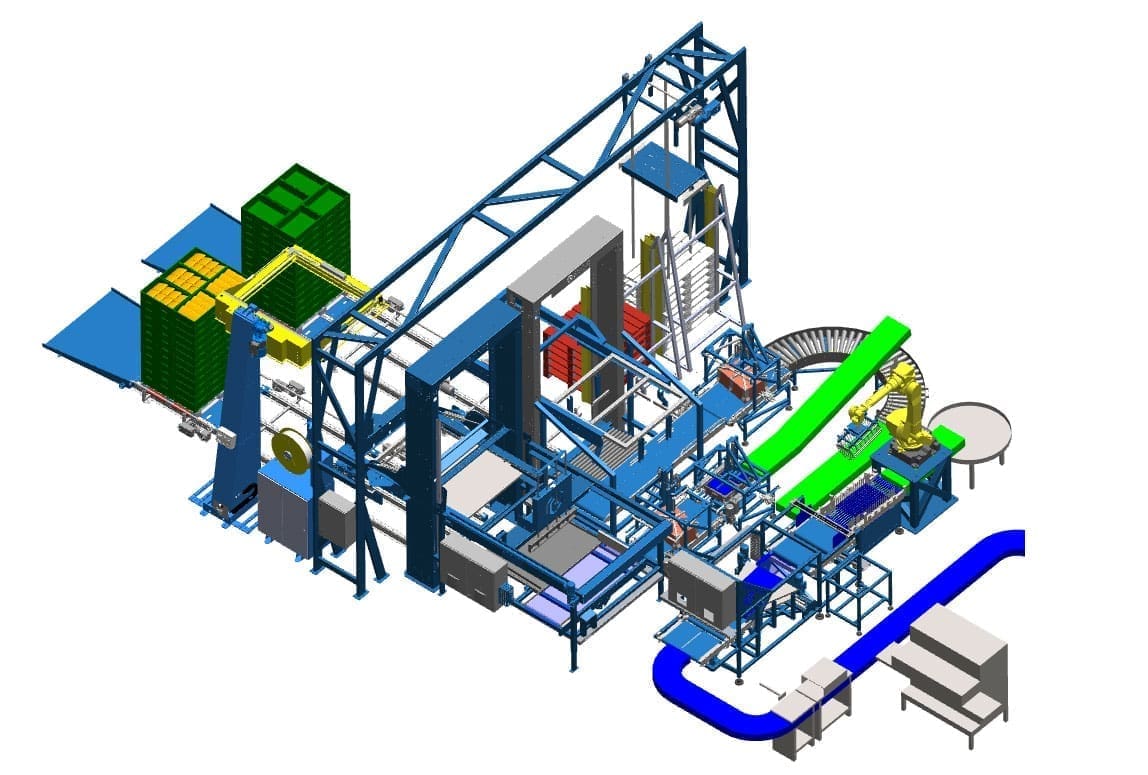

The challenge was clear: a compact solution that could handle different crates and boxes, without loss of speed or flexibility. Reintjes delivered a total solution that fits perfectly into the existing logistics line. Full pallets are automatically processed and forwarded to the right modules, without manual intervention.

The system combines a universal depalletizer with a destacker and unfolder, good for a capacity of up to 1,500 crates per hour. Change formats? That’s done with just the push of a button.

A solution that grows with you

The machine processes not only collapsible crates, but also fixed crates and boxes. This makes the system broadly applicable within TOP Onions’ various product streams. The compact setup also leaves valuable space available on the shop floor, without compromising capacity or ease of use.

Reliance on technology, built on craftsmanship

TOP Onions is known for its artisanal approach, but also knows when smart technology makes the difference. The cooperation with Reintjes is a good example of this. With a clear desire and a keen eye for quality, a sustainable and flexible solution was realized that fits the company’s growth ambitions.